Main Content

Organic Molecular Beam Deposition (OMBD)

OMBD is a method to fabricate thin films. By this procedure molecules are evaporated from a reservoir and condensed on a substrate. OMBD, which is performed in ultrahigh vacuum, has several advantages. For example, a high pureness of the evaporated material can be obtained and a clean surface of the substrate warranted. These and further properties are the reason for OMBD being one of the favorite methods to produce molecular thin films.

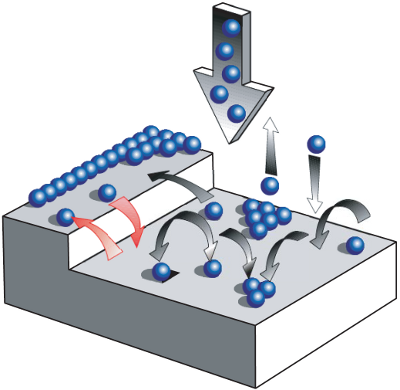

For OMBD a reservoir of molecules is heated up to a temperature at which the molecules sublime into the gas phase. By the geometry of the reservoir they are directed to the surface of interest. This is realized by the use of Knudsen cells, which are heated by means of a heating coil. Thereby, the temperature of the cells is regulated in such way that the intended deposition rate is obtained. The deposition rate is monitored by a quartz crystal microbalance (QCM). A shutter helps to precisely stop the flux of the molecules.

Figure 1: Schematice of the processes relevant in thin film growth, e.g., adsorption, (re-)desorption, diffusion, nucleation and growth of islands (phys. stat. sol. (a) 201 (2004) Schreiber).

OMBD has a lot of advantages. For example, compared to ambient conditions, in ultrahigh vacuum it is much easier to keep a sample surface clean. Additionally, the organic material can be purified by outgassing before use. Thus, contaminations by materials with another desorption temperature can be avoided. The precise regulation of the evaporation rate via cell temperature allows to vary the speed of the growth and, hence, to manipulate crystal growth. By heating the substrate during OMBD the diffusional degrees of freedom of the molecules can be increased yielding accessibility of different polymorphisms and topologies. It is further possible to produce defined film thicknesses where hardly any material is lost due to the directional molecular beam. In addition, insoluble molecule classes are accessible which cannot be prepared wet-chemically.

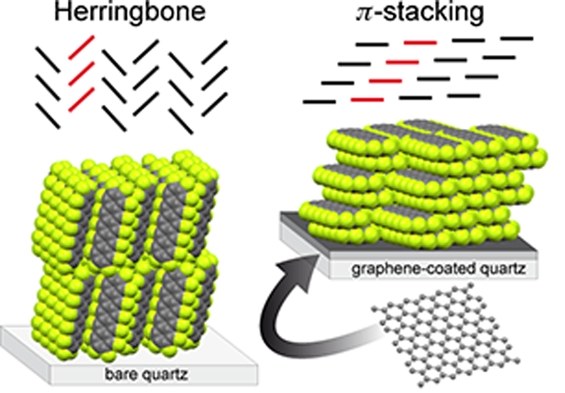

Next to the mentioned preparation parameters the template on which the film is deposited influences the growth and the orientation of molecules in a film (template effect).

Figure 2: Perfluoropentacene (PFP) is arranged in a standing herringbone or flat-lying stacked structure depending on the given template (quartz vs. graphene) [I. Salzmann et al., ASC Nano, 12, 10874-10883 (2012)]

The properties of the thin film systems prepared by means of OMBD can afterwards be examined in detail by various methods. We have diverse techniques at our disposal, such as TDS, XRD, AFM, LEED, STM, NEXAFS, XPS (see here).

Typical questions are:

• Which parameters allow to grow which crystals?

• How does the temperature of the substrate influence the topology of the thin film in OMBD?

• Which crystalline phases are accessible by means of OMBD?