Main Content

Wet-Chemical Processes

Immersion

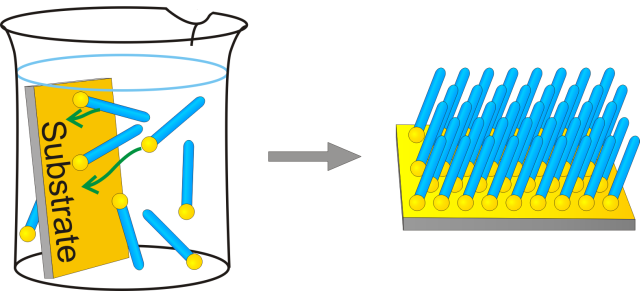

A monolayer of an organic molecule can be formed by immersion of a metal or metal oxide substrate in highly diluted molecular solution. Thereby, the molecules covalently bind to the substrate surface and organize in a process of self-assembly. After extraction from solution, loosely attached residues can be easily removed by rinsing with solvent. The self-assembled monolayer (SAM) essentially changes the surface characteristics such as wettability, hydrophobicity, friction and biocompatibility, thus providing a basis for further modification. Most common are alkane thiols adsorbing on gold surfaces.

Wet-chemical sample preparation is an attractive alternative to Molecular Beam Deposition (OMBD), especially as there is no need for ultrahigh vacuum and expensive laboratory equipment. Futhermore, this preparation method allows parallel production of several samples.

Microcontact Printing

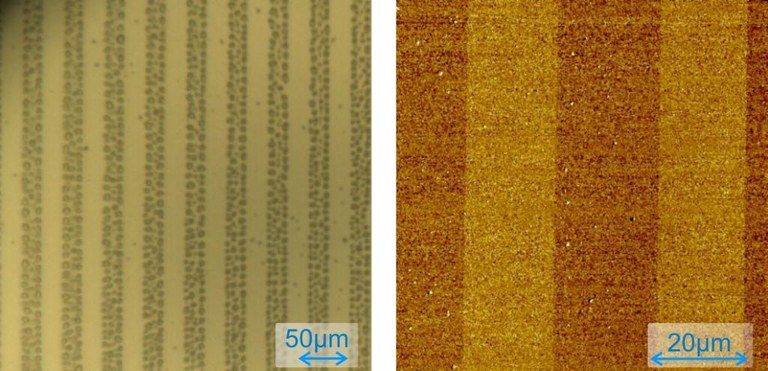

Microcontact printing (µCP) represents a quite easy but versatile and reliable method to create micrometer patterns of self-assembling monolayers. The principle is similar to a potato print: a PDMS stamp with a defined relief is soaked with solution of a molecule, dried and brought in contact to a substrate. At the regions of direct contact molecules move from the inside of the stamp to the metal surface where they bind. This method can also be used for selective deposition of nanoparticles or enzymes. The stamp is formed by casting a polymer on a photolithographically structured silicon master.

The result is a defined selective coating, which, for example, can be identified in the friction-sensitive mode of the atomic force microscope (DLFM, see right figure), under the optical microscope due to the wetting of fine water drops (left figure) or by the formation of a diffraction pattern. Unmodified areas can be backfilled with other appropriate molecules and thus passivated or functionalized.

Spin Coating

Spin coating is a method that enables deposition of thin homogeneous layers of, for example, polymers or nanoparticles. For this purpose, a drop of the material is placed on a substrate which is rotated afterwards. Tuned by the duration and rotational speed, a thin film of the material spreads over the sample and remains upon drying/evaporation of the solvent. Examples are PDMS films on glass or nanoparticle layers on SAM-functionalized gold surfaces.